Listen and subscribe to our podcast: Via Apple Podcasts | Spotify | Stitcher

KEEWATIN — The deep pits of the Iron Range feel quite otherworldly in a state known for its flat topography.

Here, trucks the size of houses traverse vast canyons that have been carved away over decades by explosives and excavators. It is a constantly evolving landscape.

The Munson family of St. Louis Park asked Curious Minnesota, the Star Tribune's reader-fueled reporting project, to find the state's largest machine — inspired by 9-year-old Julien's new Transformers toy. Our hunt for answers in January revealed many candidates in the iron mines of northern Minnesota.

Little did we know that we would soon be seeing those mammoth machines up close at the invitation of Pittsburgh-based U.S. Steel, which organized a tour of their Keetac mine. Our tour was an epic field trip for adults and children alike (and will soon be an episode of the Curious Minnesota podcast).

I was eager to wake up at the crack of dawn and make the long drive north because I've realized that the Iron Range is a bigger deal than I once thought. The rocks buried beneath northern Minnesota essentially fueled America's success story as the country's largest source of iron ore.

Cities like my hometown of New York City grew upward in the early 1900s with the help of steel beams packed with iron from the mighty Mesabi Range. Minnesota mines also supplied much of the raw material for the steel artillery that America sent overseas in World War II.

American steel production still relies on the Range as its primary source of virgin domestic iron. It is now concentrated from lower-grade ore, known as taconite, than what was available here a century ago.

But the Range is also an adventure to visit. For kids, it is like seeing Tonka toys come to life.

"They're excited about the big trucks," said mother Aimee Munson as we embarked into the mine's undulating terrain. She was looking forward to the pellet plant.

"I just love a factory tour," Munson said. "You just learn what really is behind the things that you use every day. Like our stainless steel water bottles. It's got to start somewhere."

'Minnesota's Grand Canyon'

We began our tour looking out at the expansive, multilevel "pit." I remarked that the place feels like the Grand Canyon.

"That's what we said when we were driving up," Aimee responded. "It's like Minnesota's Grand Canyon."

The land here is constantly changing as the mining follows the underground ore deposits. And one day, when the mine closes and they stop pumping groundwater, it will become a lake.

"When you work here ... things will look different on Monday from when you left on Friday," said Steve Andrie, who oversees mine operations at Keetac.

Taconite mining begins with carefully orchestrated explosions, which occur roughly every week at Keetac. Tall drills excavate holes in neat rows to plant explosive charges 40 feet down, which are then covered with rocks to contain the energy underground.

"You see all the little mounds in a row? That's a blast pattern," Andrie said.

Far in the distance were the behemoth trucks the kids had been eager to see.

"They look like an ordinary truck from all the way over here," Julien said.

Supersized vehicles

The scale of the vehicles soon came into focus, however, when we shuttled to one of the dump trucks and Julien and his sister Delphine climbed up to the cab — 18 feet off the ground.

"It's really big and cool," said Delphine, 12, adding that the truck was larger than she had imagined.

Feeding all these dump trucks are even larger excavators, which are the biggest portable machines on the Range. Their immense size grew clear as we climbed the several-story staircase of the Komatsu PC7000, walking past 11-foot-tall tracks and the beefy hydraulic system that keep it moving.

"This is massive, just massive," said father Nathan Munson as we reached the third floor of the machine, where the operator sits.

The best spot to take pictures was down below at the towering bucket, which takes so much abuse from chewing up the earth that its dinosaur-like teeth must regularly be replaced.

It's the "biggest bucket on the Iron Range," explained Mike Bakk, Keetac's director of operational readiness. It has enough capacity to pick up the equivalent of 44 washing machines with each scoop.

These vehicles work 24 hours a day bringing ore from the pit to the pellet plant — which also runs continuously. That's partly because of their hefty price tag. The high-tech excavators and dump trucks cost about $10 million and $5 million, respectively. The truck tires alone cost roughly $40,000 apiece — and there are six of them per truck.

"You can't have a piece of equipment that's that expensive just sitting 12 hours a day," Andrie said.

Concentrating the iron

Iron ore from the Range is shipped by boat and train to steel mills around the country and beyond, where it is melted down to make steel. In the early 20th century, iron-rich ore was so plentiful here that it could be shipped in its natural state to steel plants.

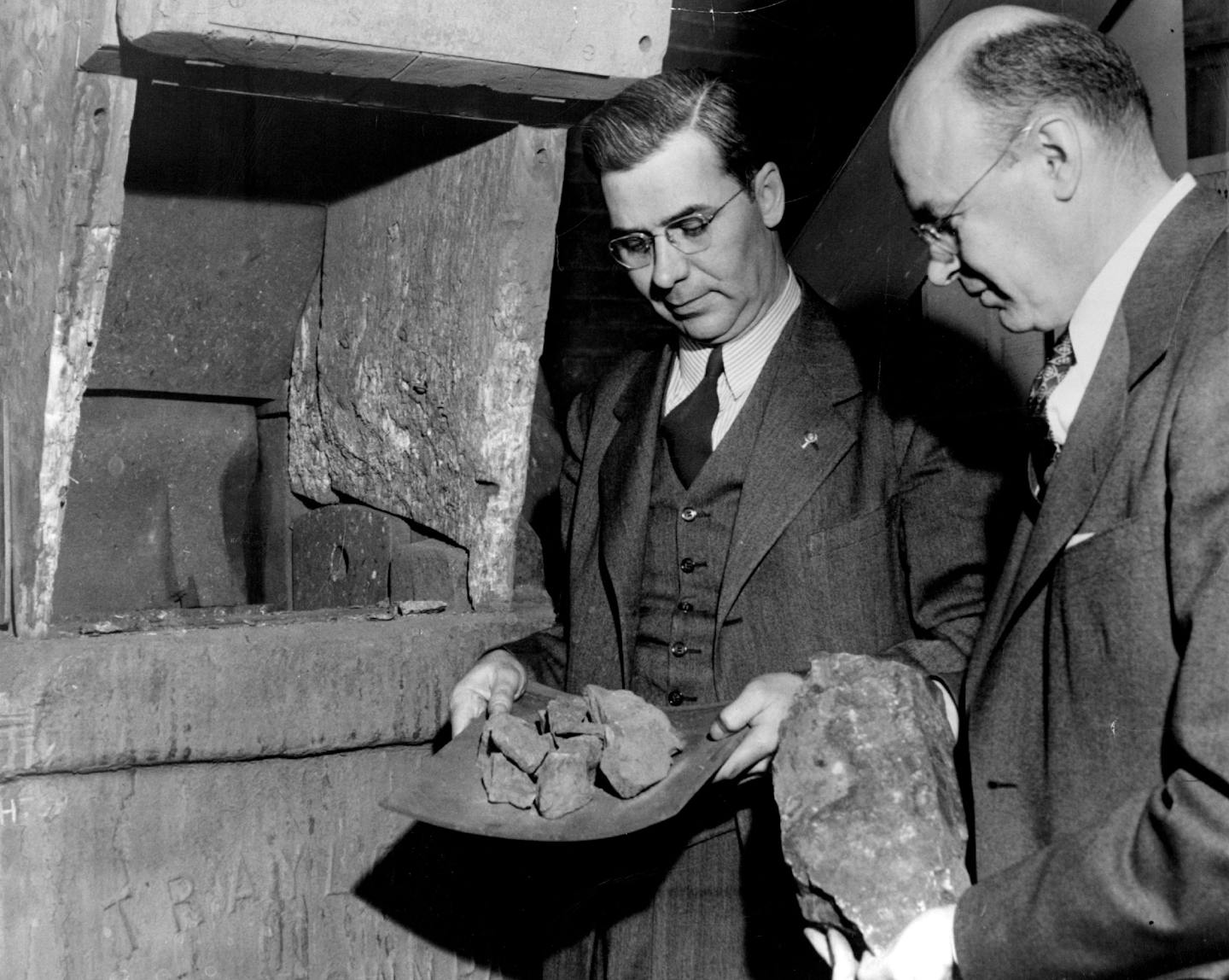

"There was very little processing that went on back then ... it was 60-plus percent iron right out of the ground," said Bakk, whose father is former state Sen. Tom Bakk. America's appetite for steel had gobbled up that good stuff by the end of World War II.

That could have been the end of the story. But researchers found a way to concentrate the lower-grade taconite — roughly 20 to 30 percent iron — into a viable substitute.

At Keetac, this happens at a large factory beside the pit, which contains the facility's most massive machines.

"Keep your hands close to your body and try not to touch anything spinning," the plant's manager, Tim Kalisch, warned us as we put on our safety gear. "It can be dangerous."

We soon understood what he meant as we gazed at a room full of rotating grinding mills that pulverize the ore into a powder. They do this by tumbling the ore with 5-inch steel balls and water inside a long cylinder that is 27 feet in diameter. It takes 7,000-horsepower motors to run these mills.

We followed a maze of catwalks to the next stop, a powerful magnet that separates the ferrous iron material from other minerals — like silica.

"If you had a piece of metal on you and you got [too close], that magnet's so strong it would suck your arm right in," Kalisch informed our group.

The iron-rich slurry is sent to an adjoining building, where a filtering machine transforms it into a cake-like substance. It's now ready for the balling drums, which turn the cake into soft, marble-sized pellets called "green balls."

A fiery end

They're called "green" because they are about to be baked in a multistage furnace and then a fiery kiln that reaches upwards of 2,300 degrees.

"It looks like a bunch of yellow stuff," Julien said before he donned a welding mask to gaze into the blazing kiln, which is a 130-foot-long rotating cylinder.

Some of the balls break up and make dust, which fuses together into large chunks of slag in the kiln. These large chunks occasionally fall into the subsequent cooling chamber, which can interrupt or damage equipment — causing costly delays.

Enter the shotgun.

I noticed several extra-large shotgun shells lodged in the grate of our observation platform. I was informed that, to keep the process moving, workers sometimes use a shotgun to fire eight-gauge slugs into the cooler to break up the pesky chunks.

At the end of the process, the cooled taconite pellets are roughly 66% iron and ready to be fed into a blast furnace at a steel mill.

Back in the conference room where we started the day, I asked Bakk what message he hoped to convey from the tour.

"People seem to have lost connection with where things come from," Bakk said. "They don't come from the store. They come from the ground. It's grown or it's mined."

Take the lid of a pickle jar, for example.

"People don't even realize like that was a rock at one point in time," Bakk said. "And it comes from here. So mining is a very necessary part of having a society like this."

If you'd like to submit a Curious Minnesota question, fill out the form below:

Read more Curious Minnesota stories:

What did the topography of the Iron Range look like before it was mined?

How important was the Iron Range to winning World War II?

Is Duluth the most inland seaport in North America?

Was Duluth once home to more millionaires per capita than any other U.S. city?

Why did Finnish immigrants come to Minnesota? (And no, they're not Scandinavian)

Where does Twin Cities electricity come from and how is it delivered to homes?